We are seeing a growing demand from pharmaceutical companies for support in developing new dosage forms and drug delivery systems beyond the traditional oral route, as they explore innovative ways to improve drug efficacy, safety, and patient compliance. At Conscio Group, we are committed to providing our clients end-to-end support throughout the entire drug development process: From hard-to-make formulation development, in vitro bioanalysis of topical products by Franz cell percutaneous absorption or the manufacturing of transdermal therapeutic systems and orally dissolving films. Today we speak with formulation scientist Dr. Oana Mocanu and development analyst Martina Matisková about alternative routes of drug administration, advanced in vitro testing techniques and the latest regulatory trends.

We begin with Dr. Oana Mocanu, PhD in macromolecular chemistry and specialist in biomaterials at the formulation department of Conscio’s German subsidiary, Gen-Plus:

Q: I think we all understand tablets or capsules, but what can you tell me about the new drug delivery systems you are helping develop?

“Recently, we have seen an increased demand for alternative drug delivery systems like transdermal therapeutic systems (TTS) or patches, and orally dissolving films (ODFs). These systems are sometimes used as an alternative to conventional oral dosage forms due to their quick release of active pharmaceutical ingredients (APIs) and convenient administration. TTS deliver medication through the skin and into the bloodstream, bypassing the digestive system and liver, and are commonly used for medications that are difficult to absorb orally, such as hormones or nicotine replacement therapy. ODFs are thin, flexible films that dissolve quickly, delivering the APIs. They provide a convenient and easy-to-use alternative to tablets or capsules and can be used for a wide range of applications.”

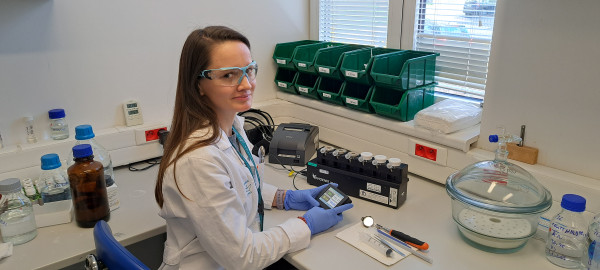

Dr. Oana Mocanu at Gen-Plus’ Formulation Lab

Q: Is this why you specialize in these patches and films?

“Well, it is broader than that. At Gen-Plus we do have a long history in the development of TTS and ODFs, but also with many unconventional dosage forms and formulations. We have a unique capability to take a new drug formulation from scratch, develop the process, and bring it to Phase I clinical phase. Our strength lies in our well-trained team of experts in the field of solid, semi-solid and liquid dosage forms, patches, thin films, micro/nano-emulsions, hot melt extrusion, personalized medicine like 2D and 3D printing, IMP manufacturing and high containment technologies. Our analytical department offers a diverse range of analysis, including permeation studies, in vitro dissolution, particle and solid-state characterization, and HPLC.”

Q: How can you tell if these novel delivery systems perform better than, let’s say, a simple tablet?

At this point, Martina Matisková joins our discussion. With a master’s in food technology and processing, she is one of the specialists in percutaneous in vitro testing at the R&D department of Conscio’s Czech subsidiary, Quinta-Analytica:

“When developing dosage forms and delivery systems it is vital to evaluate drug delivery efficiency. Some clients wish to develop generic topical versions of already existing drugs; others plan to deliver the API through a new technology. We use different techniques depending on the drug we are dealing with. In the case of TTS, ODFs and topical products like creams, lotions or gels for pharma and cosmetics, we look at percutaneous absorption: The process of the drug penetrating the skin and entering the bloodstream. Percutaneous absorption can be tested in vitro with Franz diffusion cells; a type of instrument that mimics the skin’s outermost layer. We measure amount of drug that penetrates through the instrument, speed of absorption, or drug release from the delivery system.”

Q: So, you use these Franz cells to compare the delivery efficiency of these new drugs with their reference products?

“Yes. We can use these assays as an in vitro bioequivalence to compare reference products and their topical generics, but in the case of investigational medicinal products (IMPs) we may compare among different formulation candidates. Franz cells are used to carry out in vitro release and in vitro permeation testing (IVRT and IVPT) for physicochemical characterization and early-stage bioavailability and efficacy, aimed at optimizing absorption and galenic formulation. Depending on the goal, these assays may need to be performed under GLP or GMP.”

Q: And why in vitro? Couldn’t you use a more traditional test? And how do you know these in vitro tests are accurate?

“Bioequivalences for certain products cannot be performed with classic bioanalysis of blood samples because they may not adequately reflect the pharmacokinetics of API release. The FDA and EMA have issued guidelines such as the Draft Guideline on Topical Products or SUPAC-SS Guidance stressing this point. Moreover, EMA’s Guideline on Bioequivalences allows for the application of biowaivers to in vitro testing with Franz cells; making it possible for manufacturers to skip some preclinical and clinical assays if they can produce relevant in vitro data. For new formulations, IVRT with artificial membranes is usually sufficient, but in bioequivalence studies of topical generics or characterization of transdermal patches, current guidelines require comparative IVPT assays with actual skin.”

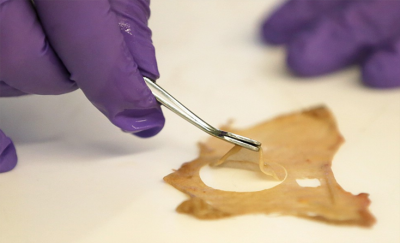

When diving into the topic of skin samples, Dr. Mocanu talks about tissue providers and the analytic particularities of patches and films:

Tissue preparation for Franz cells testing

“Finding the right kind of tissue can be a more limiting factor than analytical expertise, but fortunately, we collaborate with multiple tissue providers for our permeation studies. We use human skin samples from surgical procedures, as well as buccal, nasal, small intestinal mucosa and other tissues. For TTS and ODFs we also perform IVPT studies with Franz cells. First, we place the tissue on the cells and the patch or film on the top. That aside, collection and HPLC analysis is similar to what we would do with a cream. As ODFs are intended to dissolve in the mouth saliva, we also perform flow-through cell (FTC) dissolution testing; another in vitro method different from Franz diffusion cells which mimics the physiological conditions of the human oral cavity to assess dissolution rates.”

Q: All this sounds pretty advanced. Let’s say I am a manufacturer of conventional generics considering a switch to topicals or delivery systems. Why should I entrust you with my project?

“One of our strengths is our capability to offer end-to-end support throughout the entire process. Before we mentioned our expertise in multiple dosage forms and technologies. Speaking about TTS, we can produce them at different scales using table-top equipment or our two coating lines. The resulting laminate can be converted, and patches automatically packed. With regards to ODFs, we can also produce API-containing or placebo films for 2D printing. Our ODFs can be formulated for rapid absorption or optimized palatability and have a single or multi-layer system, with dissolved, dispersed, or emulsified APIs. We develop the API inks ourselves and print with a 2D printer or continuous PML equipment. Our films, inks and 2D printers were developed in parallel. Quite a success story!”

Martina Matisková at Quinta’s R&D Lab

Martina Matisková further talks about how her team is prepared to adapt to their clients’ most specialized requests:

“Our clients can count on our capabilities and flexible approach to meet their needs. Let’s take percutaneous absorption as an example: This is a specialty service compared to other assays and yet we are equipped with three Franz cell units: Two Hanson Topical automatic instruments with a combined capacity of 12 cells plus a Phoenix DB-6. We understand each test substance and experimental setup may require a customized approach, and are proficient in variations of standard methods, such as the Saarbrückener model for increased precision. Before we mentioned FTC dissolution testing, which we can perform with our Sotax AT7 apparatus 4. FTC testing is useful for ODFs, but also for special topicals that require high throughput with simultaneous samples or continuous sampling.”

Q: Surely, everyone claims to be adaptable and go the extra mile. You also said demand for these services is increasing. Can you provide specific examples about what makes you stand out?

“At Quinta-Analytica we cater to a diverse range of clients, from developers and manufacturers of topical products to generic companies looking to obtain biowaivers through IVTP. Our experience in in vitro testing began in 2018, with a pilot study for betahistine orodispersible tablets using porcine mucosa. Since then, we have been involved in numerous topical projects. A recent one with a clotrimazole cream for fungal skin infections was especially tricky: Time was a critical factor for our client and FTC testing was to be used instead of Franz cells. We faced delays and methodological challenges, as sometimes happens in R&D, but despite everything we persevered, and the client could submit the study data to the agency last February. I am pleased to add we maintain a great working relationship.”

Adding to Ms. Matisková’s examples, Dr. Mocanu has some additional ones to offer:

“At Gen-Plus we usually work with clients from the drug delivery systems field. We are collaborating with a client from a renowned German R&D group on an ODF project for clinical studies. Our ODF and ink development research is ongoing, and we’re looking at new formulations to improve 2D printing compatibility. We also worked on a cannabis project where we had to test whether the API, tetrahydrocannabinol (THC) in a spray patch, permeated through the skin. Another of our current projects involves assessing whether a customer’s product effectively goes through the buccal mucosa, which has become increasingly challenging due to limited access to these tissues after the COVID-19 pandemic. We are proud to work with such a diverse range of projects.”

Hanson Topical Franz Cells closeup

Q: You certainly seem quite busy! And do you see this trend continuing for the long-term?

Martina Matisková answers first with a take on the latest regulatory developments:

“The latest regulatory changes have opened new market opportunities for topical products, and we are experiencing a surge of requests for our IVRT and IVPT services. In fact, we had to strengthen our testing capabilities to meet the demand. More producers are benefiting from the biowaivers to launch new topical generics. The EMA has been working on their draft guideline for topical products since 2018, and while the final version has not been published yet, the second public consultation period ended in April 2021, so it really shouldn’t take much longer. All will depend on the direction marked by the authorities and the final guideline version, but we do not expect major changes after the last consultation. In conclusion, I am confident the trend will continue.”

Oana Mocanu agrees with her colleague and expands on the points made so far:

“Patches and films can be tested with the methods outlined in EMA’s draft, so its completion can only have positive effects on these technologies. TTS and ODFs have recently become a hot topic due to their advantages over conventional dosage forms. ODFs can be more convenient than tablets for patients who have difficulty swallowing. TTS provide sustained release, improve bioavailability, reduce side effects, can be applied discreetly, and solve issues associated with other delivery types, such as enzymatic digestion, acidic hydrolysis, food-drug/drug-drug interactions, or gastrointestinal irritation. TTS are used for pain relief, smoking cessation, contraception, motion sickness, osteoporosis, cardiac disorders, and transcutaneous immunization is becoming an alternative route for vaccination.”

Olbrich Labcoater for TTS and ODFs

As part of the same corporate group, the formulation and analytical teams at Gen-Plus and Quinta-Analytica work closely together with a centralized project management system. Oana and Martina share some closing remarks about their day-to-day work under Conscio:

“As a formulation scientist, it doesn’t matter to me whether the analytics are performed at Gen-Plus or Quinta, as we are all working towards the same goal. Using the example of a TTS: If we have a project with a customer that involves both formulation and analytical aspects, the formulation team would start developing and producing the TTS, which would then be sent to analytics for testing. We have regular weekly update meetings with the Prague teams to discuss the progress of ongoing projects. We are sharing staff, expertise, and instruments to deliver the best possible outcomes.”

“We also collaborate with our colleagues in Munich on various projects. Right now, we are developing an API-containing ink for a 2D-printed ODF. Our R&D team is testing solubility and stability of the ink which will be applied to the placebo substrate to create the final ODF, while our analytical colleagues are validating and verifying some pharmacopeial methods. We are happy to collaborate with our counterparts and learn from each other. As part of Conscio Group, we are all growing together.”

CONSCIO GROUP is a European leading customer-centric contract research & development service provider for the pharmaceutical industry delivering customized end-to-end drug development solutions within the areas of innovative R&D and formulation, analytical QC and clinical solution as well as small scale manufacturing. Conscio Group members include Quinta-Analytica (Czechia) Gen-Plus (Germany) EL Labs (Slovakia) LVA (Austria) and HyServe (Germany). Visit www.consciogroup.com for more information.

Article by Albert Pineda